From lead aprons being held together with duct tape to attenuation holes the size of baseballs, after servicing over a million X-ray garments, we’ve seen it all.

How can you tell that your apron needs repairs or even replacement?

Some signs of wear and tear are obvious, while others are not.

Most imperfections that can lead to serious safety issues are only visible through X-ray imaging, which we recommend performing on your garments annually.

In this article, we’ll go over the five most common signs of lead apron wear and tear we see, along with related details and tips, plus recommendations for repairs or replacement.

1. Core Material (Attenuation Material) Cracks and Tears

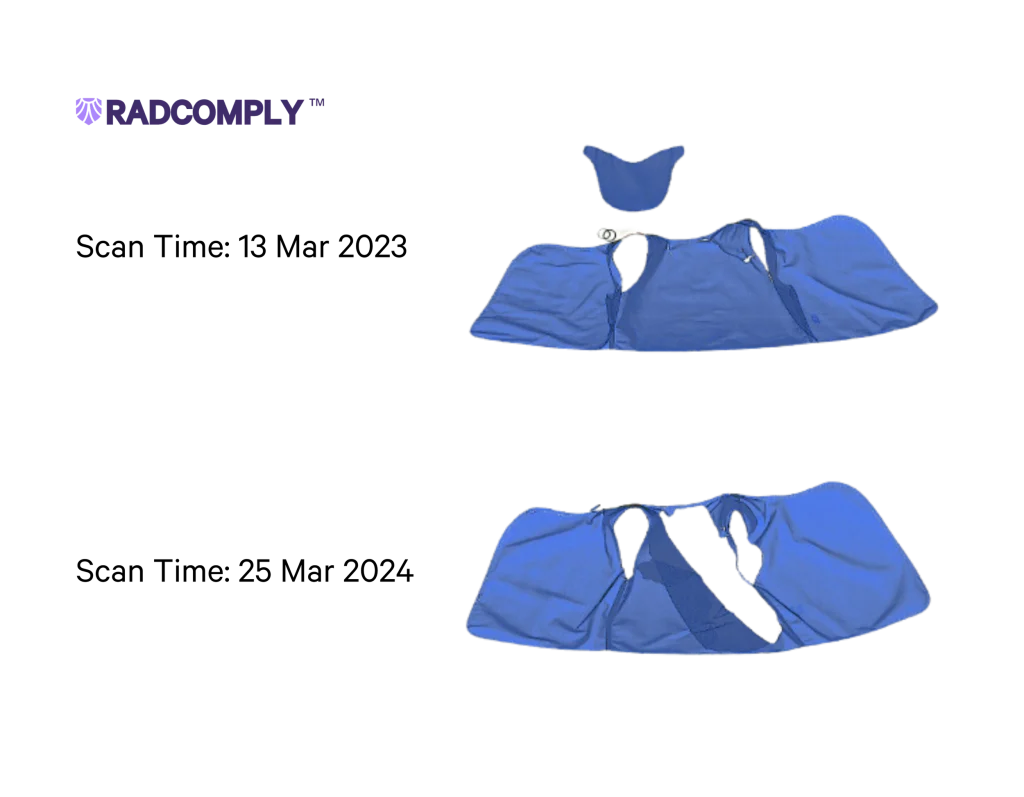

Garments with even minimal attenuation damage frequently return with moderate or severe damage the following year. Cracks or tears in the attenuation material can result from a lead apron’s age and improper storage.

It doesn’t take long for cracks and tears to expand, much like how a chip on a windshield can quickly spread across the rest of the glass.

Physicians K. Lambert and T. McKeon performed a study to establish lead apron rejection criteria. Their findings suggest aprons should be replaced when defects exceed:

● 15 mm² when over critical organs (thyroid and gonads)

● 670 mm² when along the seams, in overlapped areas, or on the back

● 11 mm² for thyroid shields

Annually X-ray scanning your garments is the best practice to ensure there are no defects beyond the rejection criteria outlined above, regardless of your state’s regulations. Allowing damage to lead aprons exceeding what’s outlined above puts staff at risk of radiation exposure or infections.

Visual and palpation tests aren’t enough to reveal all potentially dangerous attenuation material damage. It is doubtful you’ll feel a hole 15 mm² through the nylon material and your gloved hand. We’ve X-ray-scanned thousands of garments and often find tiny holes or tears visual inspections missed.

Unfortunately, attenuation cracks and tears cannot be repaired.

2. Cosmetic Issues

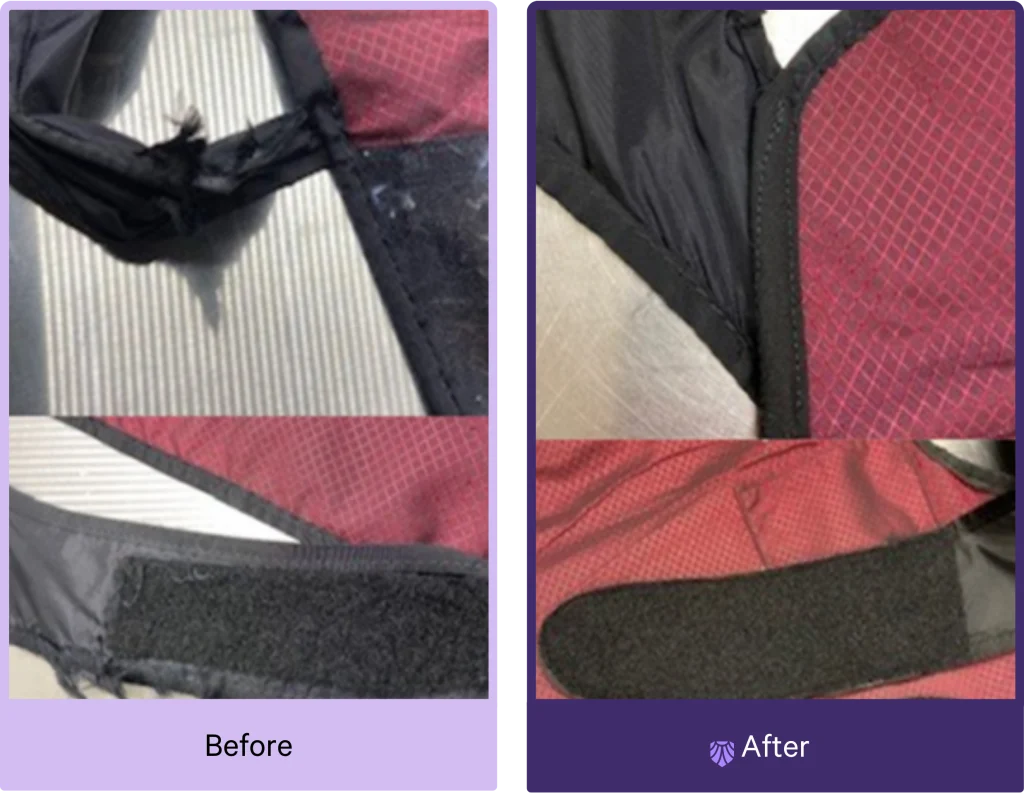

Cosmetic wear and tear is prevalent, which is why we offer complimentary repairs as part of our service. These issues typically do not affect the garment’s safety unless they prevent the wearer from correctly wearing it. You can help extend the life of your garments through routine repairs.

Here are some of the most common issues we see (and can often repair!).

Broken Buckles

Buckles on various garment types often deteriorate, break over time, or get damaged while stored. This poses a safety concern due to creative workarounds (like duct tape) used to then properly wear the lead garment. Such workarounds can result in the garment being worn improperly, causing discomfort and potential radiation exposure.

Ripped Hanging Straps

Ripped straps are most commonly seen on lead skirts. These skirts are heavy, and even with proper storage, the straps wear out over time. A broken strap often leads to improper storage, such as laying a skirt on a hanger or draping a skirt over a C-arm or a rack, which can crack the attenuation material.

Worn Velcro

The Velcro on lead apron straps deteriorates over time. This can become a safety concern as it may prevent the garment from being worn correctly, leading to discomfort and potential radiation exposure.

Torn Binding

Frayed or torn binding on aprons is a common issue. If not addressed early, it can lead to tears in the fabric covering the attenuation material, leaving it exposed and vulnerable to damage. Auditors typically issue a citation when they spot attenuation material due to holes in the fabric.

Spots & Stains

Stubborn spots and stains are common, whether from casting materials or areas worn down by velcro hooks. While these issues rarely pose a safety risk, they can be an eyesore.

Also, consider what a dirty or stained lead apron conveys to the patient. The condition of the garment reflects the quality of care at that facility.

3. Broad Lines or Creases

Creases in the attenuation material are typically caused by folding an apron and improper storage. These folds are noticeable during inspections, appearing as wavy folds in an X-ray image. There is no reason for concern if they disappear or smooth out when the apron is flat, but keep an eye on the width of the lines and note any worsening changes.

4. Pin Holes

Pin holes aren’t always caused by wear and tear, but they’re worth mentioning because we often receive questions about them. Pin holes are sometimes created during the manufacturing process. They are usually fine, depending on placement and size.

● Many hospital protocols state that pinholes near the seams of the garment are typically safe.

● Some protocols state that pinholes that occur away from the fabric’s seams are okay if they are faint—less than 0.5mm in size.

● Pinholes larger than 2mm or occurring multiple times within a garment should be inspected closely for safety concerns.

5. Bunching

Bunching is when the lead, or attenuation material, falls towards the bottom of the apron.

Wearing an apron with bunching is uncomfortable because the lead’s weight isn’t evenly distributed across the garment. It is also dangerous because there is no lead protection towards the top of the garment, near the wearer’s chest.

The most common cause of bunching we see is when lead garments aren’t hung properly. The lead pulls away from the seams in the shoulders due to its weight.

Make sure you hang your garments by both straps on a metal hanger or a lead apron hanging rack to prevent bunching.

Key Takeaways: When to Repair vs. Replace Aprons

● Annually X-ray scanning garments is the best way to identify holes, cracks, and tears in the attenuation material.

● Aprons should be replaced when defects exceed 15 mm² when over critical organs (thyroid and gonads), 670 mm² when along the seams, in overlapped areas, or on the back, and 11 mm² for thyroid shields.

● Repairing cosmetic issues early will extend the life of your apron.

● Proper storage and regular maintenance is the best way to prevent premature wear and tear.

Let RCS Handle Your Lead Garment Care

The best way to prevent wear and tear of your lead aprons and other X-ray garments is to have RCS perform routine inspections and repairs during quarterly deep cleaning and disinfection.

RCS spent over a decade developing a proven best-practice process to keep our customers safe, including a proprietary two-step cleaning and disinfection process that yields the best outcomes defined by the CDC.

RCS will repair broken buckles and straps, replace worn velcro, sew torn and frayed binding, and clean spots & stains at no additional cost with a service contract.

Contact RCS today or view our website for detailed information on all our services.